RES

HEATSEAL BARS AND TOOLS

The RES sealing tool is a heat sealing bar with a heat sealing band and a matching counter bar which are tailored to your individual sealing application.

By combining it with the system components, you obtain a customized system configuration.

RESISTRON HEATSEAL BARS AND TOOLS

We design your tool in the desired contour to suit your sealing application and machine design. The sealing tools are available in straight versions with and without cooling as well as for contour and 3D applications. The bars can be produced from a few centimetres up to several meters. We design the heatsealing band, the appropriate base and the Teflon tape individually to suit your film properties and your application.

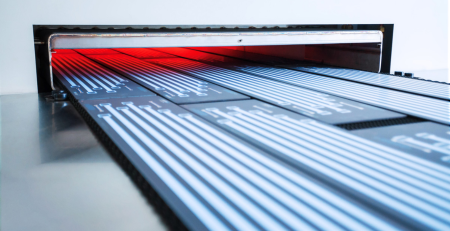

Straight sealing bars with a heat sealing band are widely used in film sealing processes. Owing to their good heat conduction, small mass and electromagnetic compatibility, they are generally manufactured from alloyed aluminum and have a rectangular section.

The body of the bar is mostly 30, 40 or 60 mm high and 10, 15 or 20 mm wide. The length ranges from a few centimeters to several meters.

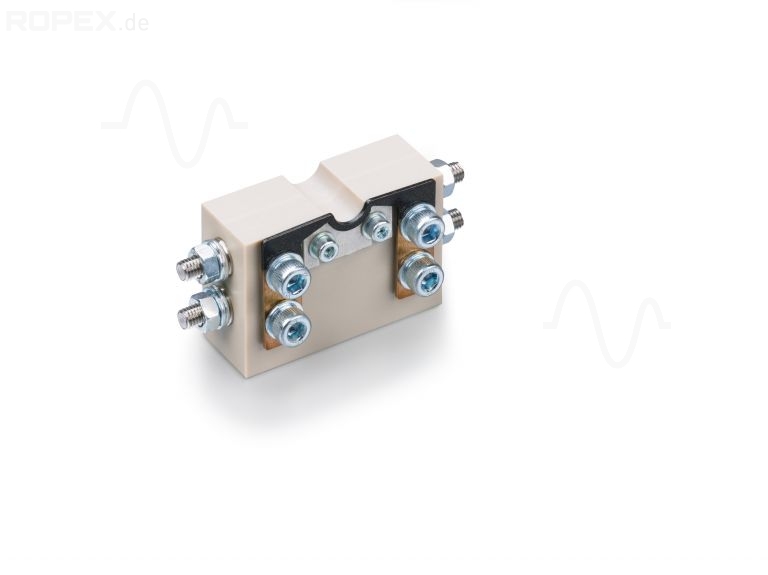

The bars can be equipped with coolant holes in the longitudinal axis on request. They are usually shipped by ROPEX fully assembled with bar end blocks, an underlay for the heat sealing band and teflon tape.

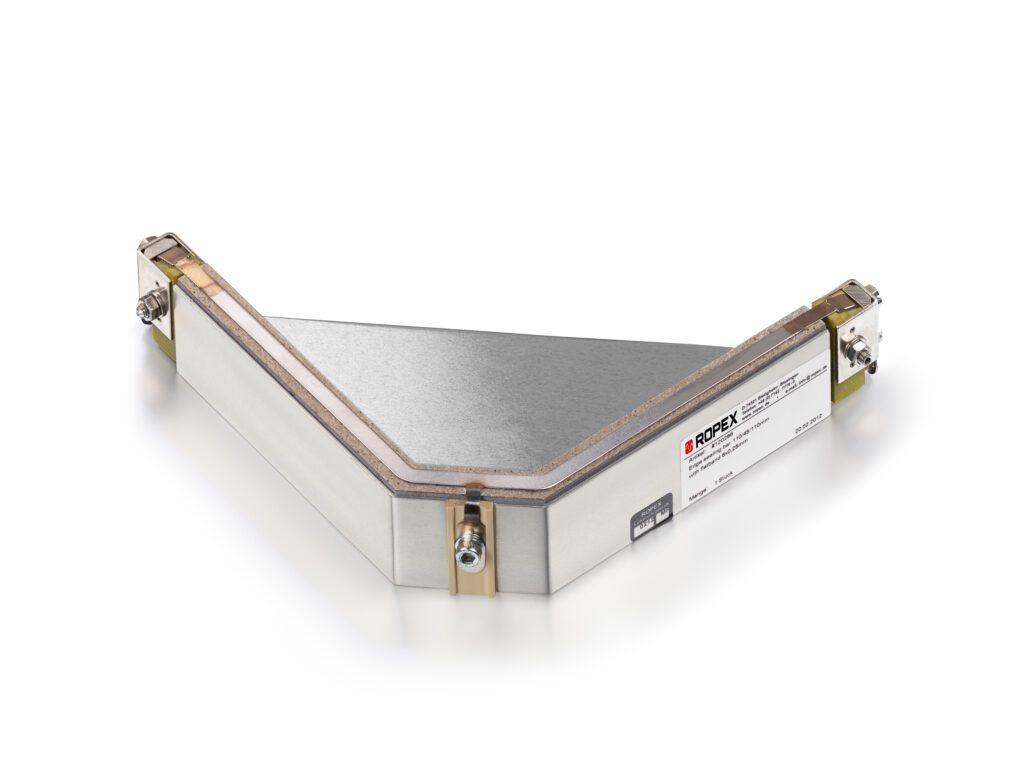

Flat, contoured sealing tools are usually custom-made products for one specific customer, where the heat sealing tool and counter bar are designed together to ensure that they interact perfectly.

Angular, circular, rectangular or curved contours can also be supplied depending on the task at hand. Precise laser cuts guarantee extremely close tolerances and consistent reproduction for complex band contours. The thickness, width and coating of the heat sealing band are adapted to the application.

The principal challenge here is to achieve a perfect balance between the temperature distribution, current input, expansion and alloy.

For our customers we create innovative applications to find the individual sealing solution. We can define the ideal “magic triangle” – heat, time and pressure – for your needs.

We would be happy to test the feasibility of your special application and suggest an alternative solution where necessary. A perfect balance between your application and the sealing bar is key.

Heat sealing bands also allow you to design three-dimensional contours due to their elasticity. We are thus able to manufacture complete sealing bars for 3D contours. Spouts are a typical example here.

A flat film is fused onto both sides of a rigid, convex spout; it forms the top of a pouch or bag with a screw-type or tube connection often encountered in medical applications.

The challenges are similar to those presented by 2D contours, except that a thin film is additionally bonded to a hard, three-dimensional plastic. The sealing bar contour, heat sealing band and counter bar must be perfectly executed.

INDUSTRY SOLUTIONS

Our solutions are used in a wide variety of industries and we look forward to implementing applications in new industries.

You need a customized solution?

We will be happy to advice you!